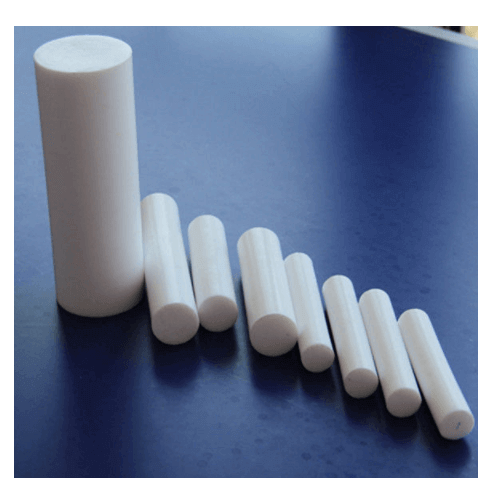

PTFE (Teflon) Rod

PTFE Rod (Polytetrafluoroethylene), commonly known by the brand name Teflon®, is a high-performance engineering plastic renowned for its exceptional chemical resistance, low friction, and non-stick properties. It operates effectively across a wide temperature range, from -200°C to +260°C, making it suitable for extreme environments. PTFE rods are highly resistant to most chemicals, UV radiation, and moisture, and they exhibit excellent electrical insulation properties. Due to its low coefficient of friction and non-reactive surface, PTFE is commonly used in seals, gaskets, bushings, bearings, electrical insulators, and chemical processing equipment. Its easy machinability allows for custom components in demanding industrial applications.

PTFE Rod – Frequently Asked Questions (FAQs)

1. What are the common applications of PTFE Rods?

PTFE Rods are used in a wide range of industries due to their excellent chemical resistance and low friction properties, including:

Seals and gaskets for chemical processing equipment

Bushings and bearings to reduce friction in mechanical systems

Insulators in electrical and electronic components

Valve seats and pump components in corrosive environments

Laboratory equipment resistant to harsh chemicals

Food-grade applications due to its non-stick, non-toxic properties

2. What are the key properties of PTFE Rods?

PTFE Rods are known for their unique combination of properties:

Extreme chemical resistance: Inert to most acids, bases, and solvents

Wide temperature range: Operates from -200°C to +260°C

Low coefficient of friction: Excellent for reducing wear and energy loss

Non-stick surface: Resists adhesion of most substances

Excellent electrical insulation: High dielectric strength for electrical applications

Non-toxic and food-safe: Suitable for food processing equipment

3. Can PTFE Rods be used both indoors and outdoors?

Yes, PTFE Rods are suitable for both indoor and outdoor applications:

UV resistant: Does not degrade under prolonged sun exposure

Weather-resistant: Maintains properties in harsh outdoor environments

Moisture-proof: Hydrophobic, making it ideal for wet conditions

4. Is PTFE Rod easy to machine and fabricate?

Yes, PTFE Rods are highly machinable:

Can be cut, turned, milled, and drilled with standard machining tools

Soft material: Requires sharp tools to prevent deformation during machining

Precision fabrication: Suitable for custom parts with tight tolerances

5. How does PTFE compare to other plastics like Nylon or UHMWPE?

Chemical resistance: PTFE is superior to both Nylon and UHMWPE

Temperature tolerance: PTFE withstands higher temperatures

Friction: PTFE has a lower coefficient of friction

Mechanical strength: PTFE is softer and less impact-resistant than Nylon or UHMWPE, making it less suitable for load-bearing applications without reinforcement

6. Is PTFE Rod food-safe?

Yes, PTFE is FDA-approved for food contact applications:

Non-toxic, non-reactive, and resistant to contamination

Used in food processing equipment, seals, and non-stick surfaces

7. How do I clean and maintain PTFE Rods?

PTFE requires minimal maintenance:

Easy to clean: Non-stick surface repels dirt and residues

Chemical-resistant: Can be cleaned with strong chemicals without damage

Simply wipe with a soft cloth and mild detergent if needed

8. Is PTFE Rod eco-friendly and recyclable?

PTFE is recyclable, but recycling facilities for PTFE are limited due to its high chemical stability. However, it is:

Environmentally stable: Does not degrade or release harmful substances over time

Reusable: Can be re-machined or repurposed in many applications

9. What sizes and diameters are available for PTFE Rods?

PTFE Rods are available in a wide range of diameters and lengths:

Standard diameters: From 3mm to 300mm (custom sizes available)

Lengths: Typically available in 1-meter or 2-meter lengths, with custom cuts available

10. Is PTFE Rod resistant to wear and abrasion?

While PTFE has excellent low-friction properties, it is:

Moderately resistant to wear: Suitable for low-load, high-sliding applications

Less abrasion-resistant compared to materials like Nylon or UHMWPE

For high-wear applications, filled PTFE composites (with glass, carbon, or bronze) are recommended to improve wear resistance

Can’t find the exact size you require?

- We will cut any size you need. Request a custom quote!

- Get a quick quote using our Online Pricing Calculator 🧮

Reviews

There are no reviews yet.